- 3000tpd cement production lineThe TallKee EPC cement production line project includes services such as process design, equipment supply (including mechanical and electrical parts), civil engineering...

- 1000tpd cement production lineThe TallKee EPC cement production line project includes services such as process design, equipment supply (including mechanical and electrical parts), ...

- 1500t / d cement production lineTallKee EPC cement production line project includes process design, equipment supply (including mechanical and electrical parts), civil engineering, installation and commissioning, trial operation, reaching the production standard and final delivery and other services...

-

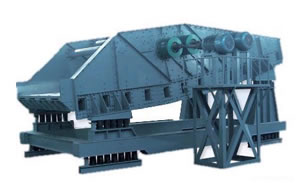

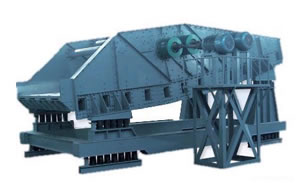

- PFS FLIP-FLOW SCREENPF series flip-flow screen is a series of high efficiency equipment specialized in sieving fine or sticky materials with high moisture content in the drying process....

-

- New Type Dry Process Cement Production LineThis new type dry process cement production line is a kind of cement production technology process mainly used for small, medium and large-scale cement plants.

Its preheater...

-

- 1500 Tons/Day Cement Processing LineOur 1500t/d cement processing line is a new type of dry process cement clinker production line. The φ3.5×54m rotary kiln has been used as rotary kiln, whose end is fitted

with five-stage cyclone preheater and decomposition...

-

- 2500 Tons/Day Dry Process Cement PlantThe main process flow of this 2500t/d dry process cement plant is as follows:

1. Crushing, Conveying and Storing of Limestone.

First, limestone is crushed

by the MB56/75...

-

- Cement Grinding PlantThe cement grinding plant mainly used in crushing and preheating of raw materials, and grinding and packaging of cement. And it is mainly applied to deal with industrial solid wastes

like slag, coal ash, coal gangues...

-

- Φ4×60m Rotary Kiln1. Production capacity: 2500t/d new type dry process cement production line.

2. Main driving speed: 0.41-4.07r/min, inclination: 4%.

3. Auxiliary transmission speed: 8r/h...

-

- Φ4.8×76m Rotary Kiln1. Specification: φ4.8×76m rotary kiln

2. Output: 5000t/d dry process cement production line

3. Inclination: 4%

4. Rotating speed: main driving part: 0.35...

-

- Φ5.0×74m Rotary Kiln1. Name of equipment: Y5074 rotary kiln

2. Application: 6000t/d dry process cement production line

3. Specification: Φ5.0×74m(inner diameter of cylinder×length)...

-

- Φ6.2×87m Rotary KilnSpecification: Ф6.2×87m

Output: 12000t/d dry process cement production line

Inclination: 3.5%

Amount of supports: 3...

-

- Lime Rotary KilnActive lime can be widely used in a wide range of industries, such as steel, alumina, magnesium, calcium carbide, papermaking field, etc. As an important auxiliary material, active lime can not

only help to improve...

-

- Vertical PreheaterAs a major device in the active lime production line, this vertical preheater is specially designed to send limestone from the upper part to the preheater body, and it can take use of 1150℃

exhaust gases, discharged from...

-

- Active Lime Production LineThis 600tpd active lime production line is a complete line that includes vertical preheater, rotary kiln, grate cooler, air treatment system, raw material conveyor system,

finished product conveyor system, raw coal grinding system...

-

- 1000t/d Active Lime Production LineTallKee Group manufactures the complete set of equipment for the 1000t/d active lime production line or active lime equipment. Our company...

-

- Lateritic Nickel Rotary KilnOur lateritic nickel rotary kiln is mainly used to smelt lateritic nickel ores so as so get nickel pig iron. So far TallKee has successfully carried

out many projects in China, such as Guangqing in Guangdong...

-

- Magnesium Rotary KilnThis magnesium rotary kiln is the main device of dolomite calcining system in the magnesium industry. And it has features of high productivity, simple structure, stable mechanical property,

precise speed and temperature control...

-

- Oxidized Pellet Rotary KilnOur oxidized pellet rotary kiln is typically designed to provide high-quality pellets for blast-furnace ironmaking. And it's able to help to improve productivity, as well

as to protect environment...

-

- Bauxite Rotary KilnOur bauxite rotary kiln can be used in a wide range of fields, such as dolomite, kaolin, bauxite, refractories, cement, limestone, vanadium minerals, activated carbon, coke, mineral powder,

alumina, magnesium oxide...

-

- Titanium Dioxide Rotary KilnThe filtered titanium dioxide hydrolysate is sent to the tail of titanium dioxide rotary kiln with certain inclination. The combustion mixing chamber at the end of kiln

head can send clean flame and hot air into the kiln body...

-

- Suspension PreheaterThe suspension preheater is mainly used as the heat exchange device in the dry process rotary kiln system. And in this suspension device, the dry raw meal and hot air flow from the rotary

kiln can exchange heat and then...

-

- Conditioning TowerOur conditioning tower is an essential equipment of dry process rotary kiln system, and is the intermediate link machine between the five-stage cyclone preheater and environmental protection

equipment...

-

- Oil Sand and Oil Shale Horizontal FurnaceTogether with Langfang Branch of China Petroleum Exploration and Development Institute, we have developed this kind of oil sand and oil shale horizontal

furnace to extract oil. Its oil extraction efficiency can be as high...

-

- Tube Grinding MillOur tube grinding mill is typically designed for grinding different kinds of ores and many other grindable materials, and it can be widely used in building materials, metallurgy, chemical industry,

electricity industry, and many other...

-

- Air Swept Coal MillThis air swept coal mill is specially used to dry and grind coal. And it is mainly consist of feeding device, main bearing, rotary part, transmission device, high voltage starting device,

and lubrication system...

-

- Slag Ball MillThis slag ball mill is a key machine mainly used to process materials from crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building material, refractory

material...

- Ф5×15m Cement MillThis Ф5×15m cement mill is a cement tube mill. It is upgraded from the traditional ball mills. It keeps all advantages of the open circuit grinding system...

-

- Ф4.6×14m Cement MillФ4.6×14 m cement mill is a closed circuit grinding type mill. Its production capacity is from 140t/h to 150t/h. It is normally matched with O-Sepa separator. It is...

-

- Autogenous MillThis autogenous mill is typically designed to grind ores and other particulate matter in various fields like building material field, chemical industry, metallurgy industry, refractory material sector,

and so on...

-

- Semi-Autogenous MillThis semi-autogenous mill, also called semi-autogenous grinding mill or SAG mill, is mainly used to grind ores and other particulate matter in different fields, like chemical industry,

mining field, metallurgy industry, building material...

-

- Overflow MillThis overflow ball mill is typically designed to grinding ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical

industry, and that...

-

- Quartz Sand Ball MillThis kind of quartz sand ball mill, also known as coal water slurry wet mill and calcium carbonate mill, is developed on the basis of German technology of ball mill, and it is widely

used to grind various chemical materials...

-

- Vertical Pre-Grinding MillThis vertical pre-grinding mill is mainly used to cut, crush and grind materials through three symmetrically rotating rollers with pressure. Together with ball mill, it can

form a circulatory pre-grinding system, circulatory hierarchical...

-

- Rolling MachineOur rolling machine is a kind of new-type cement grinding equipment developed on the basis of advanced technology, and its grinding system has integrated the rolling, scattering, separating, drying

and powder separating...

-

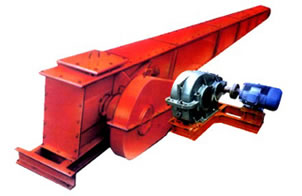

- Scatter Grader1. Name: DSF600/140 scatter grader

2. Application: Scattering and grading crushed materials

3. Amount: 1 set

4. Material: clinker...

-

- Powder SeparatorThis powder separator, usually referred to as powder concentrator, is specially designed to classify clinker and raw materials in cement plant, and together with a ball mill, it can build up a

closed-circuit grinding system...

-

- PFG180-120 Rolling MachinePFG180-120 rolling machine or roller press is used for grinding cement clinker. Its production capacity ranges from 650 to 800 t/h. The total weight is 235.0 t. This rolling...

-

- PFV4000 Scatter ClassifierPFV4000 scatter classifier is used to scatter and classify extruded materials. Its main parts include shell, shell liners, diaphragm for scattering. For detailed scope of supply...

-

- Vertical Raw MillOur vertical raw mill has various advantages when compared with other similar machines. Detailed information will be given in the following.

1. High grinding efficiency: advanced grinding...

-

- Vertical Slag MillOur vertical slag mill is typically designed to deal with industrial waste residues generated by the blast-furnace ironmaking. Due to its high physical and chemical activity, and potential

hydraulicity, the slag has been widely as...

-

- Vertical Coal MillThis vertical coal mill is typically designed to process materials in medium hardness, like soft coal or bituminous coal, and it is mainly used in positive pressure pulverizing system of soft

coal. It is widely used in electricity field...

-

- Jaw CrusherWe have three different kinds of jaw crusher for customers around the world: PE, PEX and PEV, and they are specially used in coarse and medium crushing of ores whose compressive strength is no more than

320Mpa...

-

- Impact Hammer CrusherOur PE series impact hammer crusher is typically designed to crush various ores whose granularity is no more than 500mm and compressive strength no less than 350 MPa, like granite, limestone,

basalt, and more...

-

- Spring Cone CrusherThis spring cone crusher is typically designed to process a variety of mid-hard and above mid-hard ores and rocks in different fields, like metallurgy, construction, road building, chemistry...

-

- Hammer CrusherOur PC series hammer crusher is mainly used to crush brittle mineral materials whose compressive strength is less than 100MPa, such as coal, salt, chalk, gypsum, alums, bricks, tiles, limestone...

-

- Single-Stage Hammer CrusherOur PCF series single-stage hammer crusher is typically used in cement industry to crush mineral materials whose compressive strength is no more than 200MPa, such as limestone,

gypsum, coal, malm, shale...

-

- Air Tank Pulse Bag Dust FilterThis air tank pulse bag dust filter is able to collect dust in different tanks, thus avoiding the secondary dust problem. It can deal with not only dusty gases with

general dust concentration, but also dusty gases with...

-

- CDWY Electric PrecipitatorThis CDWY electric precipitator, also known as electrostatic air cleaner or electrostatic precipitator, is a kind of new dust collection device that removes particles from flowing

gases (like air) by the force of an induced...

-

- BFRS Kiln Inlet Bag FilterAs a professional manufacturer and supplier of kiln inlet bag filter in China, TallKee can also provide you with various other machines, such as cyclone

environmental protection equipment, cement production line, cement...

-

- Monocular CoolerThis monocular cooler is an important device in the rotary kiln system. Clinker, whose temperature is 1000 to 1200℃, driven by the rotating cylinder, can take full heat exchange with air so that

their temperature can be...

-

- Horizontal Grate CoolerOur HCFC horizontal grate cooler is a kind of new energy-saving machinery for clinker, and the internationally advanced flow control technology has been employed in this machine.

Based on the advanced thermal...

-

- Belt CoolerThe belt cooler is the major machinery in the sintering systematic engineering, and it is mainly used to sinter crushed materials. It is characterized by high efficiency, good operability, economical operation

with low...

-

- Rotary DryerOur rotary dryer is typically designed for reducing or minimizing the liquid moisture content of the materials like slag, clay, limestone, etc. And it is widely used in fields of cement, chemical engineering,

metallurgy...

-

- Fluidized Bed FurnaceThis fluidized bed furnace is mainly used to scatter fine particle coal into the hot air furnace, where the coal can be burned. Inside this furnace, the coal can get a burning rate of

98%, and its heat efficiency can be as high as 95%...

-

- Double Drum Rotary DryerOur binocular rotary dryer is developed on the basis of traditional monocular rotary dryer structure, and with significant breakthrough and innovation in technology, it has more

advantages over other kinds of dyer...

-

- Triple Pass DryerOur triple pass dryer has the advantages of compact, simple and rational structure, high heat exchange efficiency, reliable operation, low energy consumption, high heat efficiency, and more...

-

- Vertical CrusherOur LP series vertical crusher is mainly used to break compound fertilizers, clinker and other materials in various fields like fertilizer industry, cement industry, metallurgy field, chemical

industry, building material field, and more...

-

- Vertical MixerOur LJ series vertical mixer, also known as vertical blender, is specially used for blending various fertilizers, clinker, and many other materials in fertilizer industry, cement field, chemical industry,

building material sector...

-

- Biaxial Wetting MixerOur ZJ/SJ biaxial wetting mixer is typically designed to mix materials or mix materials with water, and it can also be used for mixing with steam pipe to heat. It is an ideal machine

mainly used in fertilizer industry...

-

- Fertilizer Batching Scales1. The spring of its batching sensor is totally sealed and coated, thus improving its anti-corrosion capacity.

2. This fertilizer batching scales have stable performance

and strong anti-jamming...

-

- Disc GranulatorOur QPY disc granulator is typically designed to process compound fertilizers into specific shapes, and granules processed by this machine are in the same size. It has advantages of simple structure...

-

- Rotary Drum GranulatorOur TQT rotary drum granulator is an essential machine for compound fertilizer production. Its granulation ratio is as much as 70%, and its granulated products have strength more than

10N. Besides, its products have even...

-

- Ammonization GranulatorEstablished in 1994, TallKee is a professional manufacturer of ammonization granulator in China. Besides ammonization granulator, we also provide customers

worldwide with drum...

-

- Drum GranulatorThis ZL drum granulator is the key equipment for compound fertilizer industry, and quite appropriate for cold and hot, high and low concentration granulation of compound fertilizers...

-

- Spray Granulation DryerThis PZ type spray granulation dryer has integrated the spraying, granulating, and drying into one body. A series of new technologies have been used in the process of its manufacture,

such as strengthened bricks...

-

- Rotary Dryer1. the feeding temperature is about 150-350℃, and the discharging temperature is 70-90℃.

2. The production capacity depends on the components of materials and producing conditions...

-

- Rotary CoolerEstablished in 1994, TallKee is a professional manufacturer of rotary cooler in China. Besides rotary cooler, we also provide customers worldwide with rotary packer, fertilizer

vibrating screen...

-

- Rotary PackerAs a professional manufacturer and supplier of rotary packer in China, TallKee can also provide you with various other machines, such as fertilizer vibrating screen, wet process

ball mill, cement production line...

-

- Fertilizer Vibrating ScreenOur fertilizer vibrating screen is mainly used in screening and separating of semi-finished and finished compound fertilizer. And it is mainly comprised of vibrating motor,

screen box, damping spring, supporting seat...

-

- Wet Process Ball MillThis wet process ball mill is mainly used to regrind materials that have been crushed, and it is widely applied in various industries, like cement, fireproof materials, silicate products,

building materials, fertilizers, ferrous metals...

-

- Air Swept Steel Ball Mill1. The feeding size is no more than 15mm.

2. The feeding moisture content is no more than 5.

3. The feeding temperature is ranging from 300 to 350℃, and the discharging

temperature...

-

- Apron ConveyorThis apron conveyor is typically designed to transport various lump, loose or bulk materials in the horizontal or inclined direction from warehouses to crushers, conveyors or other machines. And it

is widely applied in various...

-

- Vibrating FeederThis vibrating feeder is mainly used to feed bulk or particle materials evenly, regularly and continuously in various fields. When used in sand production line, it can continuously feed materials

for crushing machines...

-

- Chain Bucket ConveyorOur SOB series chain bucker conveyor is mainly used to convey lump and granule materials that are sharp, abrasion resistant and heat resistant. It can bear high temperature as high as

250℃...

-

- Apron FeederOur apron feeder, sometimes also referred to as plate feeder, is mainly used to process 100mm-200mm materials. And it is widely used for mining, transporting and batching in cement field, fertilizer industry,

nonferrous...

-

- Chain ConveyorEstablished in 1994, TallKee is a professional manufacturer of chain conveyor in China. Besides chain conveyor, we also provide customers worldwide with air slide, cement production

line, cement...

-

- Air SlideAs a professional manufacturer and supplier of air slide in China, TallKee can also provide you with various other machines, such as bucket elevator, rubber belt conveyor, cement ...

-

- Bucket ElevatorEstablished in 1994, TallKee is a professional manufacturer of bucket elevator in China. Besides bucket elevator, we also provide customers worldwide with rubber belt conveyor,

boiling fluidized bed...

-

- Rubber Belt ConveyorAs a professional manufacturer and supplier of rubber belt conveyor in China, TallKee can also provide you with various other machines, such as boiling fluidized

bed cooler, gypsum dehydrator...

-

- Boiling Fluidized Bed CoolerThis boiling fluidized bed cooler is mainly used to cool 1-4mm granules that have been dried and sieved.

Air enters into the fluidized bed from the bottom, and then

through the air distribution plate...

-

- Gypsum DehydratorThis gypsum dehydrator is typically designed to rapidly remove moisture from gypsum. Our gypsum dehydrator mainly consists of spindle, dispersion device shell, and transmission device...

-

- Chemical EvaporatorHere in TallKee, we mainly manufacture refrigeration and petrochemical equipment, widely used in petrochemical industries, biomedical field, electronic communication

industry, food...

-

- Others Chemical ContainerHere in TallKee, we also have many other chemical containers for customers worldwide, and in the following, some examples will be given.

1. LPG (Liquefied

Petroleum Gas) storage...

-

- Electrical Control System1. XK rotary kiln monitoring system

2. Grinding plant monitoring system & micrcomputer control batching system

3. Industrial microcomputer control batching system...

-

- Lithium carbonate production lineConversion roasting: The spodumene concentrate is manually sent from the concentrate silo via the bucket elevator to the concentrate silo, and then added to the tail of the lithium carbonate rotary kiln via the disc feeder and the screw feeder...